One of the reasons there are over two million caster configurations in our catalogue is our ability to innovate by modifying existing designs to meet special requests. With our fully integrated manufacturing facility as well as our knowledgeable and creative design/engineering team, we are able to make small changes that often achieve big results. In this new e-series we look at many of our success stories in creating caster configurations to meet customers’ needs.

Reverse Rigid

Sometimes the most creative caster configurations are the product of one simple but clever thought. For years customers came to us with a predicament. Their carts were built or braced so that the only way rigid casters could be mounted is with the plate perpendicular to the direction in which it the cart travels. Mounting casters that way would have the wheels pointed in the wrong direction.

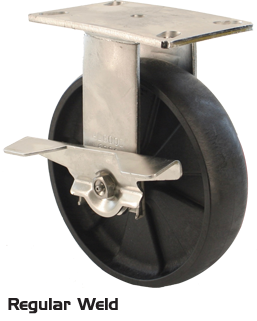

Then came the eureka moment. Our engineering and manufacturing teams devised a simple but wickedly clever solution. And because we produce our casters in our fully integrated manufacturing facility, it was easy to implement. Weld the plate so that it is perpendicular to the rig. That way the caster can be mounted as needed and will still travel in the right direction.

We call it the Reverse Rigid and until today, it was one of our best kept secrets. It’s not an option featured in our catalogue but whenever a customer needs to mount casters in that unusual way, we make it happen. We can create reverse rigids on any one of our welded casters.

The Reverse Rigid is another example of the ingenuity that comes from being Castersmiths™ – true masters of the trade. To find out more about the reverse rigid or any of our creative caster configurations, contact your Midwest Caster & Wheel, Inc. sales rep or a member of our customer service team.

Algood is proud to manufacture its casters and wheels right here in North America. For more information about Algood’s casters and capabilities, visit us our website, send us an email or call us at 888.403.2800.